Small in size, yet very skilful analyser – it has the best capabilities/price

ratio. Sensonic CGM is our alternative for large, intricate CEMS systems,

as it does not fall behind them concerning functionality and abilities,

and is far ahead in terms of expenses. It has modular construction,

and many add-ons, that makes it easy to adjust to a very specific,

individual application. Powerful PC software allows to adjust many

aspects of the work with the analyser very individually (work schedule,

analogue outputs' behaviour, data presentations, and more...)

Brochure

Brochure

Features

- Standard configuration consists up to 4 sensors (NDIR and/or electrochemical).

- Up to 8 sensors in an extreme, unique configuration

- NEW option: Large display with backlight, 4 lines x 20 characters

- Different types of gas dryers to fit the customers needs

- Compact, Split and Twin split configurations

- Data-logger with SD card for results’ collection

- Analogue outputs (both current and voltage) to control external devices

- Digital and analogue inputs to pass signals from external devices, to trigger Sensonic CGM actions

- Communication with PC via different interfaces (USB, LAN, RS485 and MODBUS)

- Different work modes to select from (continuous measurements, work with scheduler, measurements triggered with digital input, “work in-turns” - allows to measure from two different sources, and more...)

- Powerful PC program to adjust the analyser's settings and to view the results

- Rich offer of add-ons and accessories

- NEW option: Possibility to work with heated hoses. Standard lengths: 3m, 5m, 8m for 115VAC and 230VAC supply. Other hoses upon request

Compact configuration - analyser with gas dryer on a common mounting plate, all installed near the measurement place.

Split configuration - analyser and gas dryer are installed on separate mounting plates, each equipped with its own power supply module. Gas dryer is installed near the measurement place, analyser can be installed in a distance from the dryer (in the operation convenient place). Analyser can be far away from the dryer, as the gas in the between connection is suitably prepared for measurement.

Twin split configuration - analyser and two gas dryers, each on its own mounting plate, each equipped with a power supply module. Allows to perform measurements from two different locations (each dryer is installed near the measurement place). Sensonic CGM measures in turns - one cycle per location.

Gas and electric connectors (analyser’s bottom view)

The second (additional) gas channel is enabled for shorter time during the measurement phase. The additional gas channel is dedicated for the ”fragile” sensors, where they are protected against too long exposure to the gas. This way the life-time of the fragile sensors is prolonged. Bio-measurement is a typical application for the double gas channel configuration - then the primary gas channel holds sensors CO2, CH4, O2, and the additional gas channel holds the H2S sensor that is recognised as a fragile one.

Analyser designed to work with overpressure with a single gas channel. Configuration can be used in installation with slight overpressure (<1.8bar).

Tech specs

General parameters - analyser unit

| Dimensions (W x H x D) | 240 x 360 x 160 [mm] |

| Weight (depends on equipment) | 4kg ÷ 5kg |

| Casing's material | ABS |

| Mounting plate: dimensions (H x W) | material | weight | 596mm x 450mm | aluminium | 1.9kg |

| Operating conditions | T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | 0°C ÷ 55°C |

| Power consumption (analyser unit only) | 30W max |

| Data-logger: type | size | number of results | SD flash card | max 4GB | practically unlimited |

| Display: type | parameters | Backlit LCD | 20 characters x 4 lines |

| Gas pump: type | max gas flow | standard gas flow | Diaphragm | max 2l/min | 1.5l/min (90l/h) - with automatic flow control |

| Current analogue outputs | 4 outputs 0mA ÷ 20mA or 4mA ÷ 20mA |

| Voltage analogue outputs | 4 outputs 0V ÷ 5V or 0V ÷ 10V |

| Digital inputs | 2 inputs, TTL levels, floating = high level |

| Digital outputs | 1 open collector output + 2 SPDTrelays (optional) |

| Computer communication interface | B type USB socket |

General parameters - power supply unit

| Dimensions (W x H x D) | 360 x 130 x 56 [mm] |

| Weight (depends on equipment) | 1.4kg |

| Casing's material | aluminium |

| Mounting plate | Power supply is mounted on common plate with analyser unit |

| Operating conditions | T: +10°C ÷ +50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +55°C |

| Input voltage | 100 ÷ 240V AC 50/60Hz |

| Output voltage | 24V DC / 6.3A | 150W |

| Output current | 6.3A max |

| Mains fuse | 6A |

| Cable pass | 2 pcs PG-9 |

Gas dryer - MD2 gas dryer

| Dimensions (W x H x D) | 211 x 74 x 82 [mm] |

| Weight | 450g |

| Drying method | Water condensation by rapid cooling down |

| Cooler type | Based on Peltier cooling element with fan (7VDC supply) |

| Cooling temperature | Down to +4°C electronically stabilised. Dew point of outlet gas 8°C below the temperature of inlet gas. |

| Ready to operate after | 10 minutes |

| Operating conditions | T: 0°C ÷ 35°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ +60°C |

| Maximum gas flow for efficient drying | 40l/h |

| Gas filter | Integrated, with condensate reservoir and replaceable insert |

| Filter insert: length | ID | OD | material | pore size | 32mm | 15mm | 20mm | PE | 5µm |

| Condensate removal | With peristaltic pump installed in analyser's body |

| Peristaltic pump capacity | 38ml/min |

| Power supply | Via Sensonic CGM (through 15-pin D-SUB connector) |

| Power consumption | 9W |

Gas dryer - MD3 gas dryer

| Dimensions (W x H x D) |

Without filters: 110 x 205 x 160 [mm] With Filters: 145 x 240 x 160 [mm] |

| Weight | 1790g (single filter version) |

| Drying method | Water condensation by rapid cooling down |

| Cooler type | Based on Peltier cooling element with fan (12VDC supply) |

| Cooling temperature | Constant, about +1°C, output gas dewpoint about +4°C |

| Ready to operate after | 5 minutes |

| Operating conditions | T: 0°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature | -20°C ÷ 60°C |

| Maximum gas flow for efficient drying | 100l/h |

| Gas filters: quantity | material | 1 (optionally 2) | PA – body, PC – cover, viton – sealing |

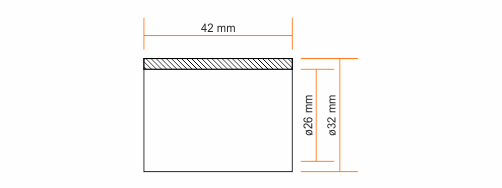

| Filter insert: length | ID | OD | material | pore size | 42mm | 26mm | 32mm | glass fibre | 2µm |

| Power supply |

Standard: via Sensonic CGM power supply (through 3-wire power cable) Standalone version via external supply module: 85V ÷ 264V AC / 24V DC |

| Condensate removal | With built-in peristaltic pump |

| Peristaltic pump capacity | 38ml/min |

Measurements of gas components

The analyser can be equipped with sensors from below list

| Compounds | Range |

|---|---|

| O2 – (EC, PP) | 20.95%, 25%, 100% |

| CO –(EC) | 4000ppm, 20 000ppm, 10% |

| CO – (EC, H2 comp) | 4000ppm |

| CO – (NDIR) | 10%, 50%, 100% |

| CO2 – (NDIR) | 25%, 50%, 100% |

| CxHy – (NDIR) | 5%, 25%, 100% |

| NO – (EC) | 5000ppm |

| NO2 – (EC) | 1000ppm |

| SO2 – (EC) | 5000ppm |

| H2S – (EC) | 1000ppm |

| H2 – (EC) | 20 000ppm |

| H2 – (TCD) | 10%, 25%, 50%, 100% |

| N2O – (NDIR) | 2000ppm |

| CHF3 – (NDIR) | 2.5% |

| CL2 - (EC) | 250ppm |

| HCl - (EC) | 50ppm |

| PID - (VOC) | 100ppm, 1000ppm, 5%, 10% |

EC - Electrochemical sensor

PP - Partial pressure

NDIR - Non dispersive infrared sensor

PID - Photo Ionization Detector

VOC - Volatile compounds

TCD - Thermal Conductivity Detector

PP - Partial pressure

NDIR - Non dispersive infrared sensor

PID - Photo Ionization Detector

VOC - Volatile compounds

TCD - Thermal Conductivity Detector

Other measurements / calculated results

| Method | Range | |

|---|---|---|

| Tgas – gas temperature | K-type thermocouple | -50 ÷ 1000°C | 0.1°C |

| Tgas – gas temperature | S-type thermocouple | -50 ÷ 1500°C | 0.1°C |

| Tamb – boiler intake air temperature | PT500 resistive sensor | -50 ÷ 100°C | 0.1°C |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa ÷ +25hPa | 1Pa (0.01hPa) |

| Gas flow velocity | Indirect, with Pitot tube & pressure sensor | 1 ÷ 50m/s | 0.1m/s |

| Lambda λ – excess air number | Calculated | 1 ÷ 10 | 0.01 |

| qA – stack loss | Calculated | 0 ÷ 100% | 0.1% |

| Eta η – combustion efficiency | Calculated | 0 ÷ 100% | 0.1% |

Drawings

Drawing #1

Sensonic CGM analyser in compact configuration with MD2 gas dryer - external view

Drawing #2

Sensonic CGM analyser in compact configuration with MD3 gas dryer - external view

Drawing #3

Sensonic CGM analyser in split or twin split configuration - external view of analyser unit

Drawing #4

Sensonic CGM analyser in split or twin split configuration - external view of gas dryer unit

Drawing #5

Gas and electric connectors panel of the Sensonic CGM analyser - bottom view

Drawing #6

Sensonic CGM analyser - main unit dimensions

Drawing #7

Sensonic CGM - MD2 dryer

Drawing #8

Sensonic CGM probe connector, Binder 680 series, 7-pin female (512O0710C)

Drawing #9

Sensonic CGM dryer connector (for the MD2 dryer only) - DB 15-pin,female (512F2151F.M)

Drawing #10

Sensonic CGM USB connector, type B

Drawing #11

Sensonic CGM waste gas fitting - pressureless version (615A0017D.M)

Drawing #12

Glass fibre filter insert, ID=26mm (614Z0010B) (for the MD3 dryer only)

Drawing #13

Hydrophobic filter 1µm (614Z0009A)

Drawing #14

Sensonic CGM RS485 socket

Drawing #15

Sensonic CGM MODBUS socket

Equipment

Analyser's standard equipment supplied along with the device

- Sensonic CGM gas analyser on a mounting plate

- Power supply unit that converts mains supply 115VAC or 230VAC to 24VDC for Sensonic CGM with power plug

- USB communication cable (5m)

- 8 analogue outputs (4x current, 4x voltage)

- 2 digital inputs for triggering Sensonic CGM behavior

- 7-pin connector for Tgas probe (thermocouple connection)

- Software CD with PC programmes and user guides

- 4 wall plugs to attach mounting plate

- condensate bag for water collection

- ON/OFF switch

Optional equipment for currently manufactured Sensonic CGM analyser

MD2 gas dryer

MD3 gas dryer

MD3 gas dryer with power supply

Stationary gas probe

Pitot tube

Heated filter

USB communication cable

Ethernet / WiFi communication interfaces

Optional equipment for older versions of Sensonic CGM analyser

RS-232C to USB converter

Bluetooth communication module